Driven by AI.

// what we offer

Smart Warehouse Approach

Smart Warehouse Approach GET STARTED TODAY →

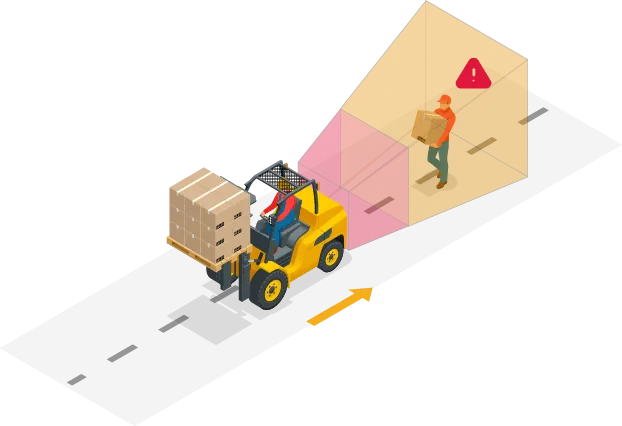

Advanced AI Safety Systems

Workforce Protection

Eliminate accidents with real-time AI detection and auto slow to safe stop technology.

Precise Monitoring

Reduce downtime and insurance costs with our intelligent forklift monitoring and analytics.

Vision-Based AI

Faster hazard detection by differentiating Humans and objects in modern warehouses.

// why choose us

Discover how our Forklift Management System can elevate your business.

01

Forklift Manage Challenges

TEKNECT’s system identifies patterns in forklift usage, highlighting units that are either overworked .

LEARN MORE 02

High Cost of Use

Real-Time Cost Visualization: The system provides a dashboard that showcases the maintenance costs associated with each forklift,.

LEARN MORE 03

High-Security Risks

Operator Authorization: The system allows only authorized personnel to operate the forklifts,reducing the risk of accidents.

LEARN MORE 04

Difficult-to-Evaluate

Working Time Tracking: TEKNECT provides accurate data on the actual working hours of each operator,

LEARN MOREHappy Customer Say

k

We successfully implemented our Forklift Management System (FMS), featuring our patented pallet counting technology.

// our service

How it works

// Transforming Forklift Management System with Advanced Technology

Stop Documenting Accidents. Start Engineering Them Out of Existence.

// Teknect

Our product

The Teknect

Global Advantage

Global Advantage

62% Near-Miss

Reduction

Reduction

70% Lower Accident

Rates

Rates

360° Blind-Spot

Elimination

Elimination

// TECHNOLOGY INDEX

Transform Your Forklift Operations with Teknect

// our clientsWe are Trusted

We are Trusted

15+ Countries Worldwide

Emily Johnson

Purchasing Manager We have established a profound and revolutionary friendship with the engineering team of Teknect; in addition, we have witnessed and recognized their professional services. Teknect is a small and sophisticated technology R&D company, and all their highly professional and systematic products are related to forklifts. Meanwhile, they attach equal importance to both the user’s experience and their needs. For AB inbev, Teknect is the very supplier that we are willing to cooperate with and seek win-win results.

Linda Brown

CEO As a developer of intelligent forklift management systems, much of Teknect’s product design and R&D is achieved by collaborating with users. Its business philosophy is to consider the customer’s needs as the top priority, and to design the product in a way most customers would expect. No matter how challenging and difficult the design is, it should be continually developed and stuck to until it begins to create value for its users.

Ran Zhu

Client of ComaBudweiser Asia Pacific Warehouse Engineering Managerpany In the finished product warehouse, our forklifts are mainly 4-ton electric forklifts with double stations, which can maximize the efficiency of the bicycle operation. In many warehouses, the operation efficiency of the finished product forklift workers can reach 60 torches per hour. The use of trams is to maximize the cleanliness of the finished wine storage environment and ensure a good experience for consumers. In order to reduce the number of batteries used as much as possible and reduce the number of battery change operations, we have begun to trial lithium battery forklifts in a number of factories.

Felix Da

Budweiser Logistics Director, Asia Pacific In the Budweiser beer warehouse, you can see a large number of various forklift models, some forklifts have even been used for more than ten years, some have just bought, some lithium tram, some diesel vehicles, showing a complex “diversity”. Due to the huge number of forklifts used in warehousing and distribution, it is inevitable to challenge the orderly operation of forklifts. Before the installation of forklift management system, forklift management is difficult to carry out centralized optimization.